Fascination About Custom Extrusion Manufacturer

Wiki Article

Top Guidelines Of Custom Extrusion Manufacturer

Table of ContentsThe 6-Minute Rule for Plastic Extrusion CompaniesHow Plastic Extrusion Manufacturers can Save You Time, Stress, and Money.Excitement About Custom Plastic ExtrusionsPlastic Extrusion Profiles for DummiesPlastic Extrusion Manufacturers Things To Know Before You Get This

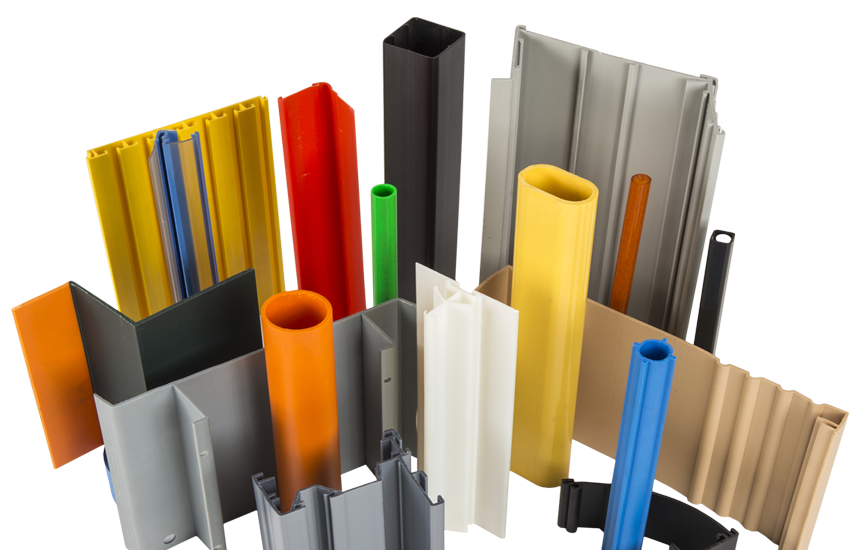

At Vip, we have years of experience production thousands of distinct custom plastic extrusions in nearly every form, dimension, as well as shade you can visualize - https://bit.ly/3sVR9mO. Our specialized hinges on making plastic profiles particularly for a certain application. You tell us what you require as well as we will certainly make it, satisfying the greatest quality criteria.From pre-prototype to post-production, ACE has the ability and also modern technology to do everything. We offer big and little firms in industries varying from automotive to clinical, with challenging product requirements to limited tolerances in America, copyright, Mexico, as well as Europe. No matter where you are or what industry you represent, you can trust ACE for individualized solution as well as consumer complete satisfaction.

That implies rapid quotation solution or product recommendation is simply a phone call away. Your questions are constantly answered without delay by our proficient service team, as well as you receive the aid you need with no delays or confusion.

Fascination About Custom Plastic Profiles

With over 100 combined years of experience in plastic extrusion, GSH Industries is a leading B2B distributor of customized plastic extrusions, tubes, and also plastic accounts in North Ohio. Our developers and also engineers can assist you in selecting the most effective products for your item line - https://www.awwwards.com/john-wynn/. We have a substantial choice of plastic materials as well as can match any personalized colors to your client's specifications - plastic extruded profiles.It is among one of the most prominent ways plastic components are presently produced because of its convenience. Customized extrusions can be developed right into intricate shapes of differing thicknesses, strengths, sizes, shades, and also also textures, as well as are fairly simple to deal with. The extrusions can additionally be created with efficiency boosting characteristics such as fire resistance, improved toughness, boosted strength, anti-friction or anti-static homes, as well as a lot more.

It can also potentially result in longer cooling time with will increase your overall production time and also costs. Sharp corners and notches produce powerlessness in the account where cracking or failing can take place since they decrease the influence resistance of the account by producing a high stress concentration. Ideally, when developing your account extrusion sharp edges must be avoided entirely rather go for rounded corners.

Plastic Extrusion Profiles Fundamentals Explained

015" (0. 381 mm). Ideally the span must be equivalent to the wall thickness of the extrusion. This adds to smoother product circulation throughout extrusion and much less stress and anxiety on the account's edges. Hollow accounts and also other details add quite a little bit of complexity over here to an extruded form. They require extra alterations to the die to make certain proper material circulation, can cause uneven cooling, and also can create areas of weakness that could result in failure.If your part must have hollows, a hollow within one more hollow is never a great suggestion. It will certainly be compelled out of shape before the extrusion solidifies - https://www.startus.cc/company/keller-plastics. If your extrusion calls for features such as legs, grooves, snap-ins, or other products inside of the extrusion it is best to create a conveniently accessible opening right into the extrusion so that you can better integrate those features.

The Buzz on Custom Plastic Extrusion Manufacturers

Understanding some clients may be not familiar with our plastic profile extrusion abilities, we have compiled a list of questions we are frequently asked. Durometer is a measurement of the material's hardness and is gauged with a tool which is pushed against the account's surface area, leading to a dial guage reading.

Usual scales are Coast A for flexible products as well as Coast D for inflexible substances. Twin durometer, or co-extrusion, is the fusion of two or more materials of differing physical residential or commercial properties into a solitary extruded piece. An example would be a stiff get rid of adaptable fingers that can be used as a gasket or cushion.

Depending on the component complexity as well as raw materials, one can estimate the costs beginning at less than $1,000. Due to varying set up expenses as well as run efficiencies, we try to limit the minimum manufacturing quantity to 1,000 lineal feet.

4 Easy Facts About Extrusion Of Plastics Described

Initially, what triggers the line. If you take a close check out an attracting for a plastic account with an intersection leg, you will certainly see there is even more mass in the location of the crossway. Given that thermoplastic materials reduce some throughout the cooling process, the crossway of 2 legs cools down at a slower price than the remainder of the profile, triggering it to reduce more because of the mass of the account.

A device developer would usually divide the flow of the two legs within the die, as well as enable them ahead back with each other as the extrudate is being compressed to the front of the extrusion die. This can in some instances develop a weld line where both melt streams are brought back together so careful tuning of the extrusion tooling is essential to decrease this line.

Report this wiki page